Make Coating Better

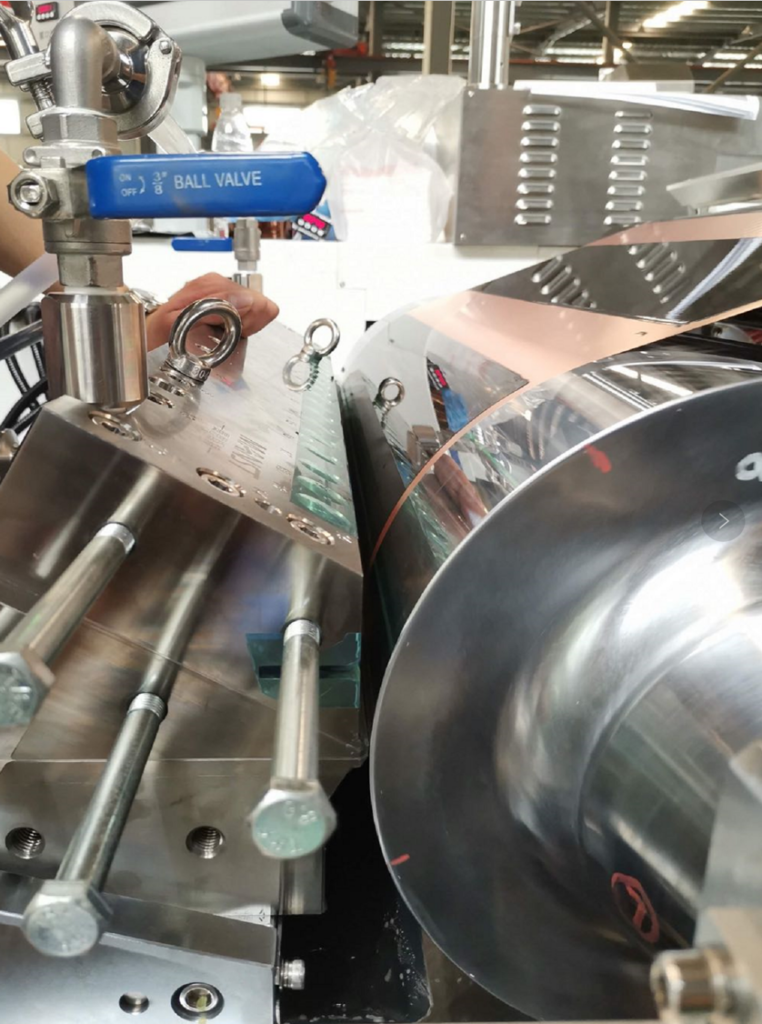

Special Designed Slot Die for Slurry of Lithion-ion Battery

Slot Die with Differential Adjustment

-

Application for cathode / anode electrode

-

Application for PVDF / ceramic on separator

-

Single or double distribution chamber

-

Coating windows A2

-

Surface harden coating treatment

-

Special selected material with high corrosion resistance and high wear resistance

-

Lip adjustment via screw

-

Straightness < ±1.5 µm

-

Flatness < ±1.5 µm

-

Cavity roughness :Ra 0.025

-

Standard width < 1600 mm

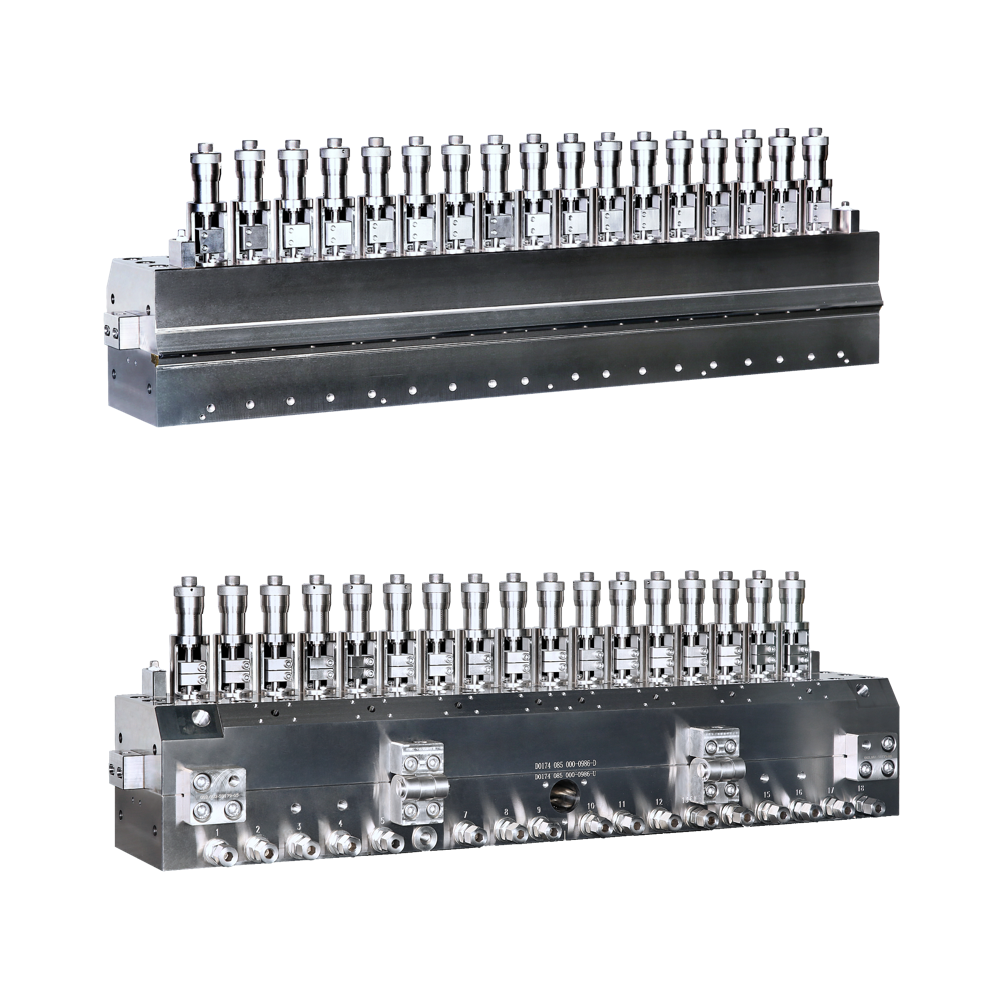

Double Adjustment Coating Die Type I

Mechanical lip adjusting slot die for cathode / anode electrode

Possible coating with active material and isolation material at same time

Single distribution chamber

Coating windows A3

Surface harden coating treatment

Special selected material with high corrosion resistance and high wear resistance

Upper lip adjustment via differential thread, lower lip adjustment via push rod

Straightness < ±1.5 µm

Flatness < ±1.5 µm

Cavity roughness :Ra 0.025

- Standard width < 1600 mm

Double Adjustment Coating Die Type II

Mechanical coating gap adjusting slot die for cathode / anode electrode

Possible coating with active material and isolation material at same time

Single distribution chamber

Coating windows A1

Surface harden coating treatment

Special selected material with high corrosion resistance and high wear resistance

Coating gap adjustment via differential head

Optional lower lip adjustment via push rod

Straightness < ±1.5 µm

Flatness < ±1.5 µm

Cavity roughness :Ra 0.025

- Standard width < 2000 mm

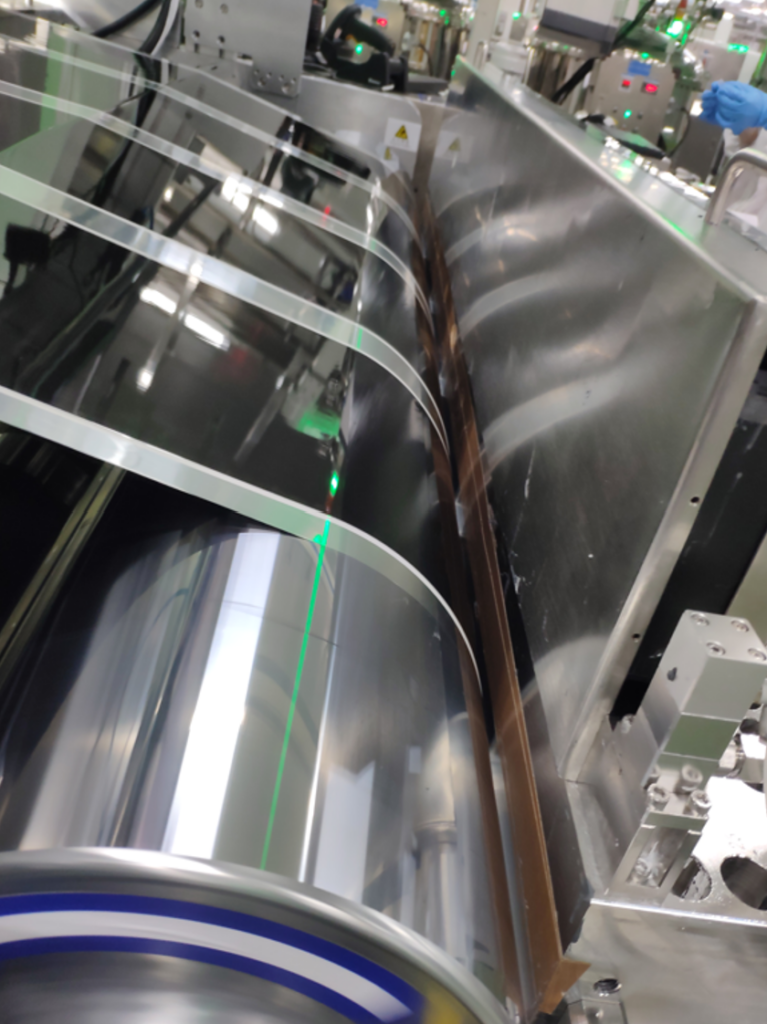

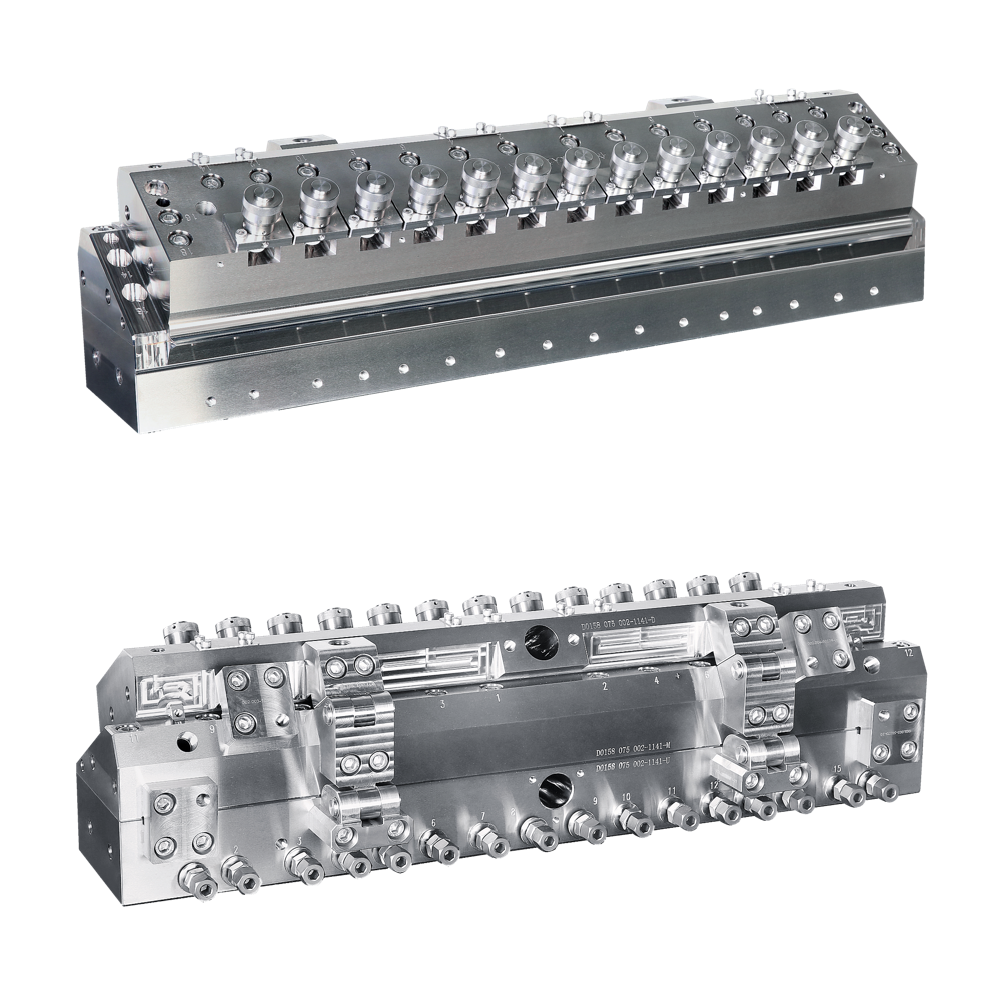

Double Layer Slot Die

Double-layer co-extrusion coating for cathode / anode electrode

Possible coating with active material and isolation material at same time

Adjustment of thickness of upper layer via differential thread or differential head

Adjustment of thickness of upper layer via push rod

Integrated adjustment unit for lip-roller distance

Patented design to solve slurry mixing issue

Surface harden coating treatment

Special selected material with high corrosion resistance and high wear resistance

Straightness < ±1.5 µm

Flatness < ±1.5 µm

Cavity roughness :Ra 0.025

- Standard width < 1600 mm

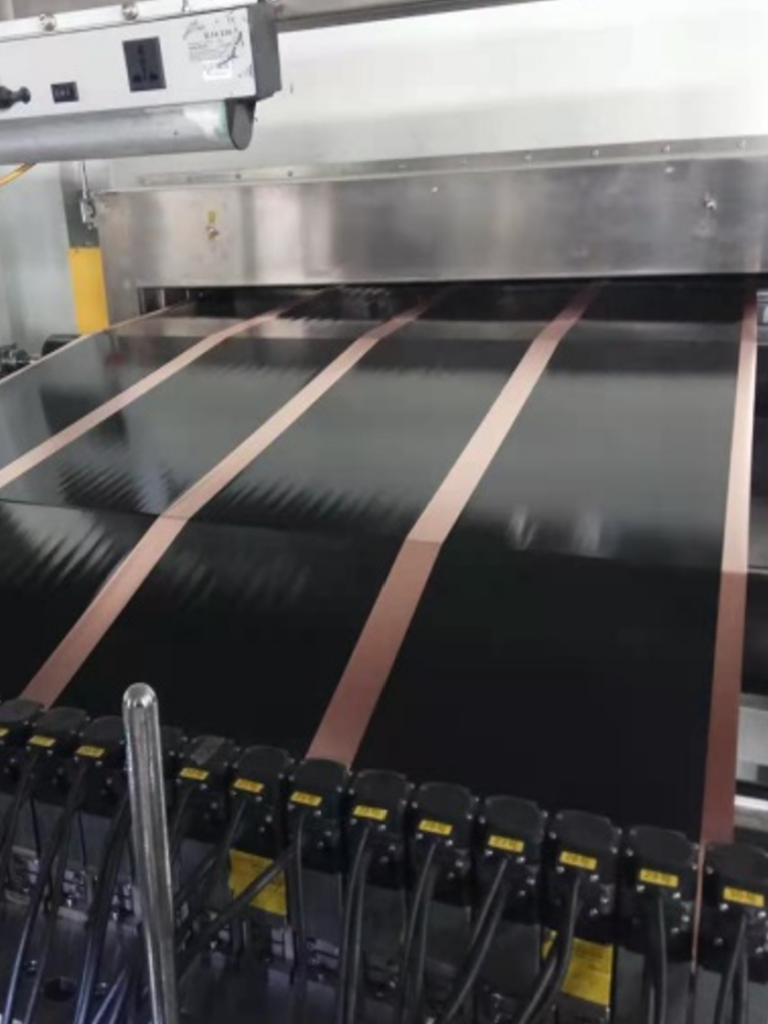

Automatic Coating Slot Die

Automatic coating slot die

Possible coating with active material and insulating material at same time

Actuator accuracy ±0.5 µm

Connection to mass loading measurement device necessary (OPC UA / Profinet)

Integrated / stand-alone MD&CD software

Double closed loop coating control based on wet and dry mass loading

Optional pressure pre-regulation system

Optional fluid temperature regulation system

Special selected material with high corrosion resistance and high wear resistance

Straightness < ±1.5 µm

Flatness < ±1.5 µm

Cavity roughness :Ra 0.025

- Standard width < 1550 mm

Lab Coater

Lab coating die for cathode / anode electrode

Application also for PVDF / ceramic on separator, primer coating

Single distribution chamber

Coating windows A1

Surface harden coating treatment

Special selected material with high corrosion resistance and high wear resistance

Coating gap adjustment via differential head

Design for easy assembling / cleaning / adjusting

Straightness < ±1.5 µm

Flatness < ±1.5 µm

Cavity roughness :Ra 0.025

- Standard width < 500 mm

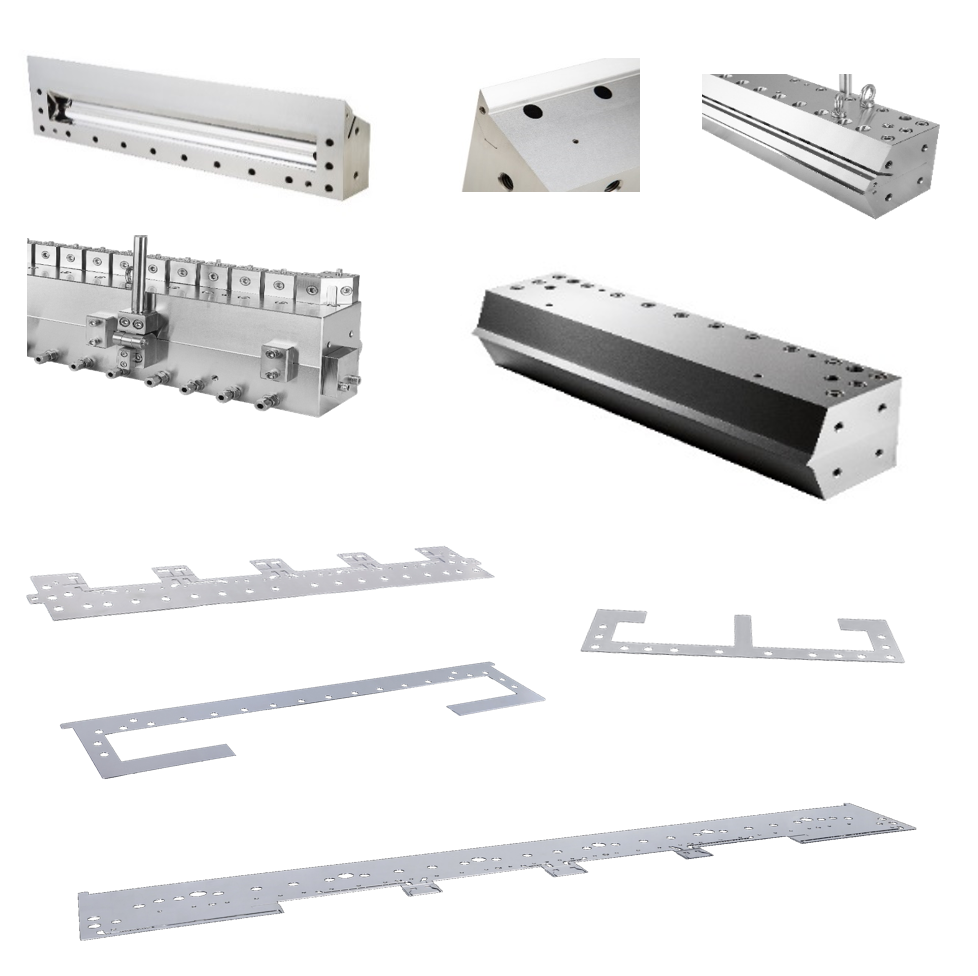

Other Slot Die Products

-

Slot die for ultra-thin layer coating ~ 20 g/m2 @ 80 m/min

-

Slot die with ultra-high corrosion resistance and wear resistance

-

Slot die with length > 2000 mm

-

Multi-component coating die

- Slot die with integrated vacuum chamber

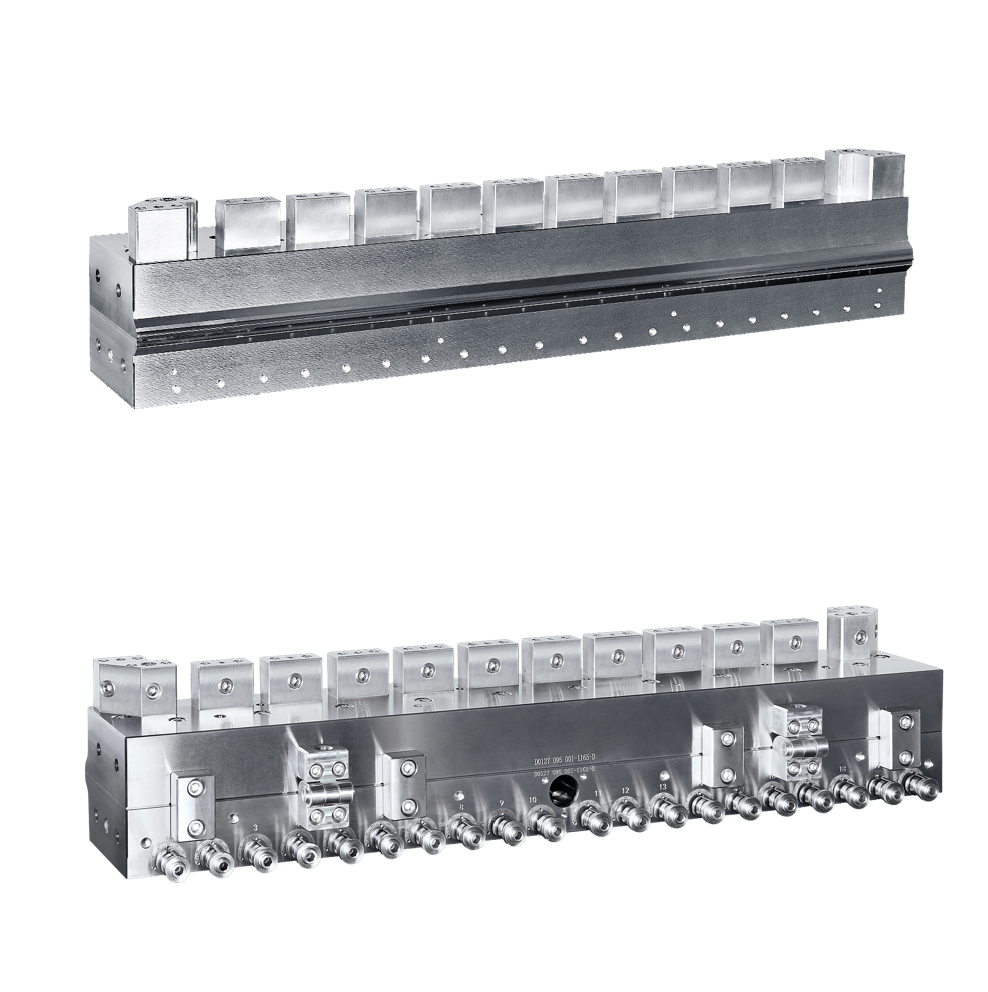

Patented Shim Design

-

Increased coating edge quality

-

Improved multi-material coating performance

-

Prevent leakage and unexpected mixing

-

Special designed fluid channel

-

Manufacture with very high precision

- Easy mounting and cleaning

Expertised Team from Design to Production

We Deliver More than 300 Unit per Month to LiB Industry

INNOVATION AND CRAFTSMANSHIP

Slot Die Products

BPE works with our partner MANST together to provide LIB slot dies from lab scale to volume production. We offer turnkey solution from special design to commission and production.

With 15 years know-how and experience in serien production of lithíon-ion battery, we deliver over 300 units every month to mainstream LIB manufacturers.

Design, material selection, manufacture and software of the slot dies are specially customerized for LIB slurries. And we focus on continueous improvement of LIB coating.

Need an advice? Talk to us:

ASIA

Mr. Zheng Liu

+86 133 5291 9203

liuzheng@manst.cn

EUROPE

Mr. Jin Geng

+49 9131 691 200

jin.geng@bpe-online.eu

ADDED VALUE FROM EXCELLENT PRODUCT

Product Competence

LiB production have extremely high requirements for process stability and product quality. Due to the complex slurry recipe, various viscosity and solid content, the coating die shall be designed to have a large process windows for a high applicability. With 15 years accompany of volume production, we have continueously improved each details in the coating process. Our slot dies have a large process windows which can covers >99% of existing battery slurries with a stable production output.

Combining precise manufacure and various adjusting mechanisms of coating parameters, we could coat with COV smaller than 0.2 in most applications. With the quantitative control process, we create decisive added value for our customers, to ensure the product quality and production rate.

By selected material and own surface technology, the product lifetime is significantly improved, specially for the most challenged slurry, such as ultra-hard nano-particle, ceramic covered NCM slurry, etc.